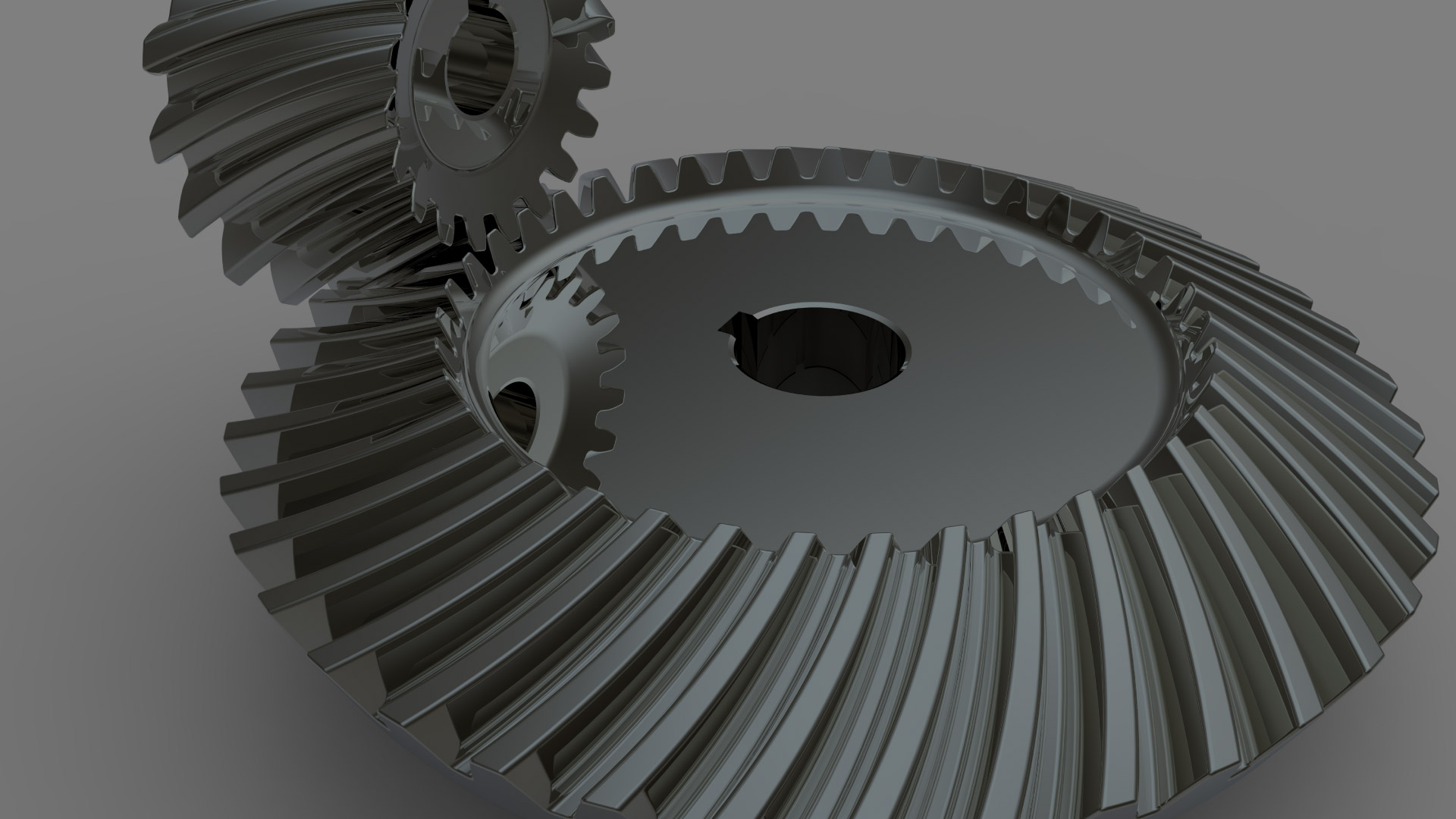

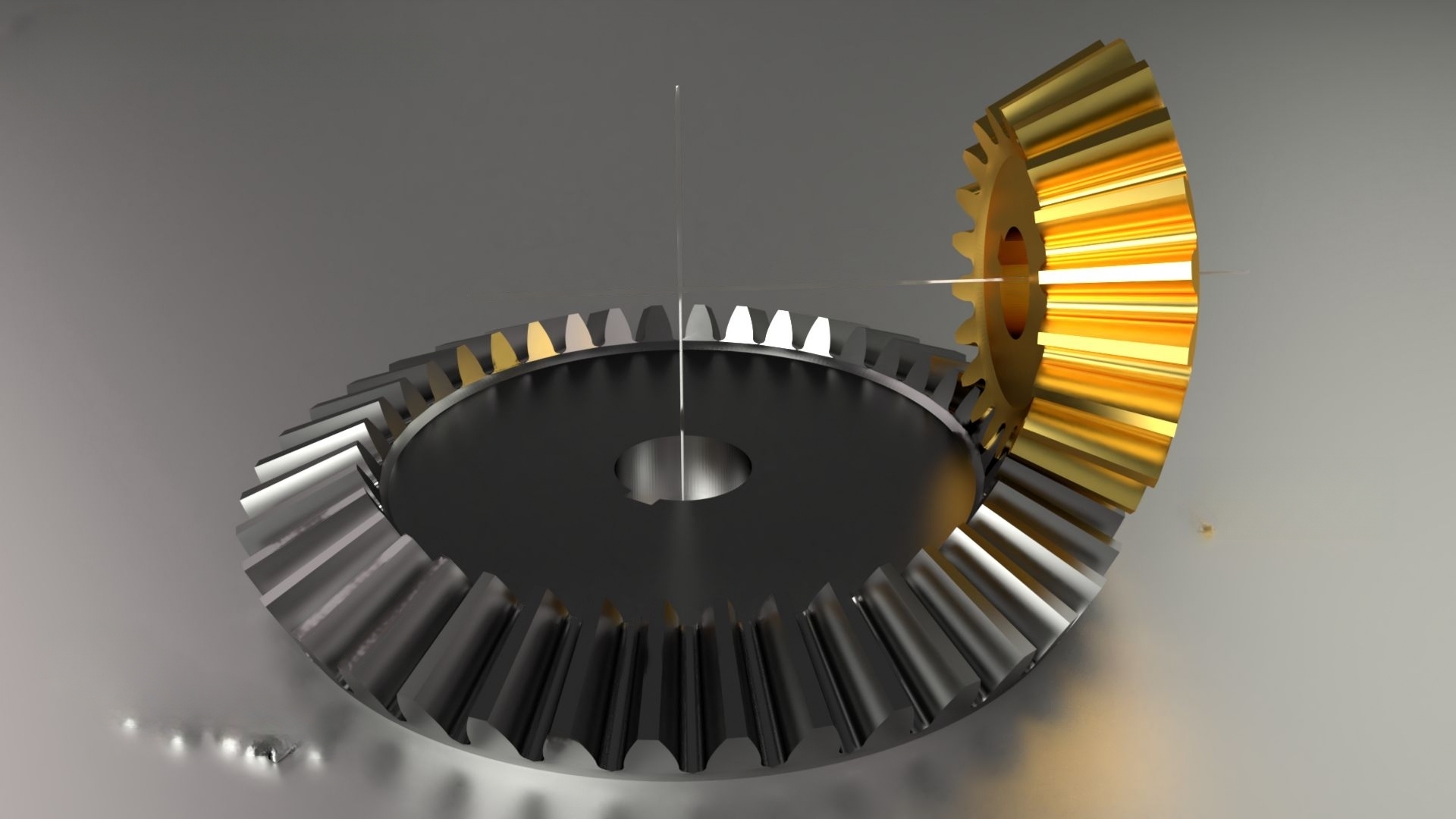

Bevel Gears

Precision Engineering for Angular Power Transmission

At Diamond Gear India, we specialize in manufacturing high-quality bevel gears for various industrial applications that require smooth and efficient power transmission at different angles.

What Are Bevel Gears?

Bevel gears are gears where the axes of two shafts intersect, and the gear teeth are cut on conical surfaces. They are designed for transmitting power between intersecting shafts at any angle, usually 90 degrees. Bevel gears can be found in applications where a change of direction is needed, such as in differential drives in automobiles or industrial machinery where precise power transmission at an angle is essential.

Types of Bevel Gears We Offer

Straight Bevel Gears

- Straight bevel gears feature teeth that are straight and converge at the gear’s axis. These are ideal for low-speed applications requiring simple, effective power transmission.

- Key Features:

- Compact design.

- Efficient power transmission.

- Affordable and easy to maintain.

Helical Bevel Gears

- Helical bevel gears offer smoother and quieter operation than straight bevel gears, thanks to their curved teeth. These gears are perfect for high-speed applications where noise reduction and durability are priorities.

- Key Features:

- High load capacity.

- Smooth and quiet operation.

- Increased efficiency and longevity.

Spiral Bevel Gears

- Spiral bevel gears are designed for more complex applications, featuring curved teeth that allow for gradual engagement and smooth power transmission, especially at high speeds.

- Key Features:

- Superior performance at high speeds.

- Low noise and vibration.

- Enhanced efficiency and precision.

Key Features and Benefits of Our Bevel Gears

Our bevel gears are designed and manufactured with the highest standards of quality and precision, ensuring optimal performance in a wide range of applications. Some of the key benefits of using our bevel gear sets include:

- Angular Power Transmission: Perfect for transferring power between intersecting shafts, usually at a 90-degree angle.

- High Load Capacity: Designed to handle heavy loads with ease, making them ideal for demanding industrial applications.

- Precision Engineering: Each bevel gear is crafted with precision to ensure smooth and efficient operation.

- Quiet and Smooth Operation: Our helical bevel gears are engineered for minimal noise and vibration, even at high speeds.

- Durability: Manufactured from high-strength materials to ensure long-lasting performance, even in tough environments.

Applications of Bevel Gears

Bevel gears are widely used in a variety of industries and applications where angular power transmission is required. Some common uses of bevel gears include:

- Automotive Industry: Used in differential drives, where power needs to be transmitted at a right angle from the drive shaft to the wheels.

- Industrial Machinery: Essential for machines that require smooth, angular power transmission in manufacturing and automation processes.

- Mining Equipment: Used in heavy-duty mining machinery to handle large loads and transmit power at varying angles.

- Aerospace: Employed in aircraft systems where precise and efficient power transmission is critical.

- Power Plants: Used in turbine systems and other energy-generating equipment for angular power transfer.

Why Choose Diamond Gear India for Bevel Gears?

Choosing Diamond Gear India for your bevel gear needs ensures that you receive the best in quality, performance, and customer support. Here’s why we are a preferred choice in the industrial gearbox market:

1. Industry Expertise

With years of experience in the gear manufacturing industry, we have the knowledge and expertise to deliver top-quality bevel gears that meet the highest standards for performance and reliability.

2. Advanced Manufacturing Technology

We utilize the latest in manufacturing technology to produce bevel gears with precision and efficiency. Our production processes ensure consistency in quality and performance, making us a trusted supplier for businesses across various industries.

3. Custom Solutions

Every application has unique needs, and we specialize in providing custom bevel gear solutions tailored to your exact specifications. From design to production, we work closely with you to ensure that your gear solution fits your application perfectly.

4. Quality Assurance

All of our bevel gears undergo rigorous testing and quality checks to ensure that they meet industry standards and deliver reliable performance. Our commitment to quality is unmatched in the industrial gearbox market.

5. Comprehensive Product Range

Whether you need straight bevel gears, helical bevel gears, or custom solutions, we offer a comprehensive range of bevel gears to meet the diverse needs of industries worldwide.

Frequently Asked Questions.

Bevel gears are used to transmit power between intersecting shafts at an angle, typically 90 degrees, in applications such as automotive differentials, industrial machinery, and heavy-duty equipment.

Straight bevel gears have straight teeth and are used for low-speed applications, while helical bevel gears have curved teeth that provide smoother, quieter operation and are ideal for high-speed applications.

Yes, we offer fully customized bevel gear solutions to meet your specific torque, speed, and load requirements.

We manufacture bevel gears from a range of materials, including high-strength steel, corrosion-resistant alloys, and other custom materials based on the application.

Get in Touch:-

Discover how DIAMOND GEARS INDIA can support your industrial needs with our extensive product range and expert solutions. Contact us today to learn more about our offerings and how we can assist you.